| EN779 | ASHRAE 52.2 | ISO 16890 | Width (mm) | Height (mm) | Depth (mm) | Initial Pressure Drop (Pa) | Air Flow (m3/hr) | No of Pockets |

|---|---|---|---|---|---|---|---|---|

| G4 | MERV 8 | ISO Coarse 80% | 595 | 595 | 330 | 45 | 3400 | 6 |

| G4 | MERV 8 | ISO Coarse 80% | 595 | 595 | 620 | 35 | 3400 | 6 |

| G4 | MERV 8 | ISO Coarse 80% | 595 | 595 | 330 | 65 | 4250 | 6 |

| G4 | MERV 8 | ISO Coarse 80% | 595 | 595 | 620 | 50 | 4250 | 6 |

| M5 | MERV 10 | ePM10 55% | 595 | 595 | 330 | 65 | 3400 | 6 |

| M5 | MERV 10 | ePM10 55% | 595 | 595 | 620 | 45 | 3400 | 6 |

| M5 | MERV 10 | ePM10 55% | 595 | 595 | 330 | 98 | 4250 | 6 |

| M5 | MERV 10 | ePM10 55% | 595 | 595 | 620 | 68 | 4250 | 6 |

| M6 | MERV 12 | ePM10 60% | 595 | 595 | 620 | 55 | 3400 | 8 |

| M6 | MERV 12 | ePM10 60% | 595 | 595 | 620 | 80 | 4250 | 8 |

| F7 | MERV 13 | ePM10 80% | 595 | 595 | 620 | 90 | 3400 | 8 |

| F7 | MERV 13 | ePM10 80% | 595 | 595 | 620 | 120 | 4250 | 8 |

SHOW MORE

Specification

Application

Gas Turbine, Compressor and harsh enviroments

Filter Frame

Polyurethane (PU)

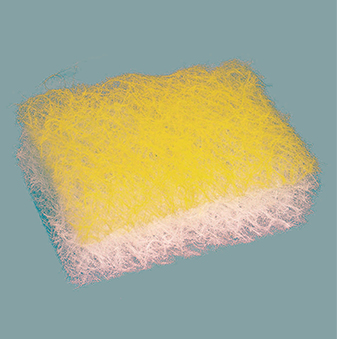

Media

Synthetic media

Max Temperature (°C)

70°C

Recommended Final

Pressure Drop (Pa)

600

.jpg)